Gold has been treasured for centuries, valued for its beauty and rarity. But did you know that gold alloys are not only limited to jewelry? In fact, there are innovative gold alloys that are revolutionizing modern applications across a wide range of industries. From electronics to healthcare, these new materials are unlocking new possibilities and pushing boundaries. In this article, we will explore the fascinating world of innovative gold alloys and discover how they are shaping the future of technology and beyond. So buckle up and get ready to embark on a journey of discovery!

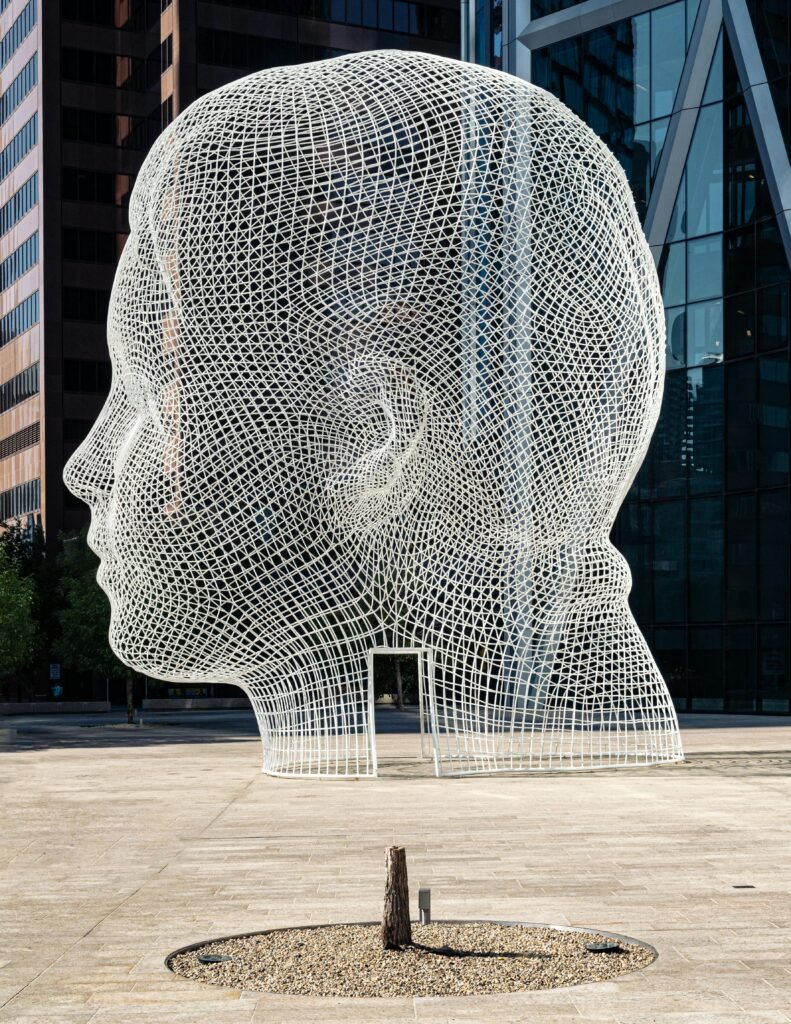

This image is property of images.pexels.com.

Introduction to Innovative Gold Alloys

Definition and Overview

Innovative gold alloys refer to a new generation of gold-based materials that have been specifically engineered to possess enhanced properties and meet the requirements of modern applications. These alloys are created by combining gold with other elements, resulting in alloys that exhibit improved strength, durability, electrical conductivity, and corrosion resistance compared to traditional gold alloys.

Importance of Gold Alloys in Modern Applications

Gold alloys have played a significant role in various industries for centuries due to their unique combination of beauty, malleability, and resistance to tarnish. However, in today’s rapidly evolving technological landscape, the demand for gold alloys with advanced properties has grown substantially. From electronics and healthcare to automotive engineering and fashion, innovative gold alloys have become integral to a wide range of modern applications.

Properties of Innovative Gold Alloys

Enhanced Strength and Durability

Traditional gold alloys are known for their softness, limiting their use in applications that require high strength and durability. However, innovative gold alloys have been designed to overcome this limitation. By carefully selecting and adding specific elements, such as silver, platinum, or palladium, to the gold matrix, these alloys can achieve remarkable strength and durability while maintaining their inherent beauty.

Improved Electrical Conductivity

Electrical conductivity is a crucial property in various industries, including electronics and semiconductor manufacturing. Unlike pure gold, which exhibits relatively low electrical conductivity due to its high resistance, innovative gold alloys offer improved conductivity without compromising other essential properties. This makes them highly desirable for applications where both conductivity and aesthetics are important.

Better Corrosion Resistance

While gold itself is highly resistant to corrosion, its alloys can exhibit varying levels of corrosion resistance depending on their composition. Innovative gold alloys have been engineered to have superior corrosion resistance, making them suitable for use in harsh environments or applications where exposure to corrosive elements is a concern. By incorporating elements such as platinum or palladium, these alloys form protective oxide layers that prevent corrosion and maintain their integrity over time.

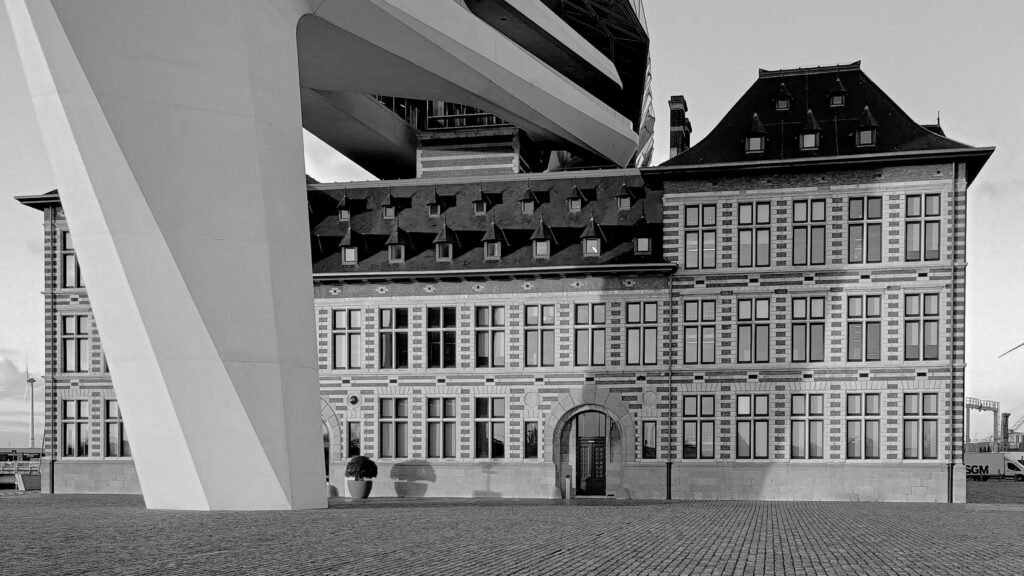

This image is property of images.pexels.com.

Emerging Trends in Gold Alloy Development

Nanotechnology Applications

The field of nanotechnology has opened up exciting possibilities for gold alloy development. Nanoscale gold alloys, with their unique properties and increased surface area, are being explored for various applications, including catalysis, electronics, and biomedical devices. By precisely controlling the composition and structure at the nanoscale, researchers can tailor the properties of gold alloys for specific applications, unlocking new levels of performance and efficiency.

Integration with Other Materials

Innovative gold alloys are not limited to standalone applications but can also be integrated with other materials to create hybrid systems with enhanced properties. By combining gold alloys with ceramics, polymers, or other metals, synergistic effects can be achieved, resulting in improved mechanical strength, thermal stability, and electrical conductivity. This integration allows for a wide range of possibilities in fields such as optics, energy storage, and structural materials.

Sustainable Gold Alloys

As environmental concerns continue to grow, the development of sustainable gold alloys has gained prominence. By utilizing recycled gold or implementing eco-friendly manufacturing processes, these alloys minimize the environmental impact associated with traditional gold extraction and production. Furthermore, researchers are also exploring the use of alternative, less resource-intensive elements in gold alloys, without compromising their performance. This ensures a more sustainable supply chain while still meeting the demands of modern applications.

Applications of Innovative Gold Alloys

Electronics and Semiconductor Industries

The electronics and semiconductor industries rely heavily on materials with excellent electrical conductivity and reliability. Innovative gold alloys are being increasingly used in these sectors for applications such as connectors, electrodes, and soldering materials. Their superior conductivity, combined with enhanced durability and corrosion resistance, makes them ideal for high-performance electronic devices, ensuring reliable performance and longevity.

Medical and Healthcare Sectors

Gold alloys have a long history of use in the medical and healthcare sectors due to their biocompatibility and resistance to corrosion. With the advent of innovative gold alloys, their applications have expanded even further. These alloys find use in medical implants, dental restorations, diagnostic devices, and drug delivery systems. Their biocompatibility, durability, and aesthetic appeal make them invaluable in the development of advanced medical technologies, improving patient outcomes and quality of life.

Automotive and Aerospace Engineering

Both automotive and aerospace engineering demand materials that can withstand extreme conditions, including high temperatures, mechanical stress, and corrosion. Innovative gold alloys, with their enhanced strength, durability, and corrosion resistance, find applications in critical components such as electrical connectors, sensors, and electrical contacts. Their ability to maintain their integrity in challenging environments contributes to the safety, reliability, and performance of vehicles and aircraft.

Jewelry and Fashion Industry

Gold’s inherent beauty and rarity have made it a cherished choice for jewelry and fashion accessories for centuries. With innovative gold alloys, designers now have the freedom to explore new possibilities. These alloys offer improved strength and durability, making them suitable for intricate designs and everyday wear. Additionally, the incorporation of alternative metals and materials in gold alloys allows for a wider range of colors and finishes, expanding the creative palette for jewelry artisans and fashion designers.

This image is property of images.pexels.com.

Advancements in Gold Alloy Manufacturing Techniques

Additive Manufacturing and 3D Printing

Additive manufacturing, including 3D printing, has revolutionized the production of complex shapes and structures in various materials, including gold alloys. This technique allows for precise control over the composition and microstructure of the alloys, resulting in tailored properties and improved performance. Additive manufacturing also offers the ability to create intricate designs and customized products with reduced material waste, making it highly desirable for jewelry, industry-specific components, and prototyping.

Casting and Forging Methods

Traditional casting and forging methods have been widely used for gold alloy manufacturing for centuries. These techniques involve melting the alloy and then shaping it through casting or forging processes. While these methods have proven effective, advancements in technology and understanding of materials have allowed for greater precision and control. By optimizing the casting and forging parameters, manufacturers can create gold alloys with improved mechanical properties, reduced porosity, and enhanced overall quality.

Surface Treatment and Coating Technologies

The appearance and performance of gold alloys can be further enhanced through surface treatment and coating technologies. These processes can provide additional protection against corrosion, improve wear resistance, and enhance aesthetical features such as luster, color, and texture. By applying various coatings or treatments, manufacturers can tailor the surface properties of gold alloys to suit specific applications, expanding their usability and versatility.

Challenges and Limitations

Cost and Availability of Innovative Gold Alloys

While innovative gold alloys offer superior properties, they often come at a higher cost compared to traditional gold alloys. The inclusion of additional elements and the development of advanced manufacturing techniques contribute to the increased production costs. Furthermore, the availability of specific elements required for alloy compositions can also impact the overall cost and supply chain stability. Manufacturers and researchers need to strike a balance between performance, cost, and availability to ensure the practicality and accessibility of innovative gold alloys.

Regulatory Compliance and Certification

As gold alloys find applications in critical sectors such as healthcare and aerospace, regulatory compliance and certification become crucial considerations. Meeting the standards and regulations set by regulatory bodies ensures the safety, reliability, and quality of the end products. The development and adoption of innovative gold alloys require manufacturers to navigate through a complex landscape of certifications and approvals, adding to the challenges of widespread adoption and commercialization.

Potential Health and Environmental Concerns

While gold itself is inert and biocompatible, the incorporation of other elements in gold alloys may raise concerns regarding their potential impact on human health and the environment. It is essential for manufacturers and researchers to thoroughly evaluate the toxicity, biocompatibility, and environmental impact of innovative gold alloys before implementing them in real-world applications. Addressing these concerns through rigorous testing and adherence to safety protocols is crucial to ensure the acceptability and sustainability of these alloys.

Future Outlook and Opportunities

Collaboration and Research Initiatives

The development of innovative gold alloys requires collaboration and interdisciplinary research efforts. Scientists, engineers, and material experts from various fields need to collaborate to explore new alloy compositions, manufacturing techniques, and applications. By fostering partnerships between academia, industry, and research institutions, researchers can leverage collective expertise and resources to drive innovation and push the boundaries of what is possible with gold alloys.

Market Potential and Growth Prospects

The market potential for innovative gold alloys is vast, given their diverse applications and superior properties. With increasing demand from industries such as electronics, healthcare, automotive, and fashion, the market for these alloys is projected to grow significantly in the coming years. This growth opens up opportunities for manufacturers, designers, and entrepreneurs to capitalize on the unique properties of innovative gold alloys and cater to the evolving needs of various industries.

Exploration of New Alloy Compositions

As research and development in gold alloy materials continue to advance, there is immense potential for the exploration of new alloy compositions. With a deeper understanding of materials science and nanotechnology, researchers can design and engineer gold alloys with tailored properties to meet specific application requirements. By continuously pushing the boundaries of alloy compositions, the possibilities for innovative gold alloys are boundless, offering endless opportunities for advancements in a wide range of industries.

In conclusion, innovative gold alloys represent a significant advancement in materials science, offering properties that surpass those of traditional gold alloys. With their enhanced strength, improved electrical conductivity, and better corrosion resistance, these alloys have unlocked new possibilities in electronics, healthcare, automotive engineering, and the fashion industry. Advancements in manufacturing techniques, such as additive manufacturing and surface treatments, further enhance the usability and versatility of these alloys. However, challenges related to cost, regulatory compliance, and potential health and environmental concerns must be addressed to ensure the widespread adoption of innovative gold alloys. By fostering collaboration, understanding market potential, and exploring new alloy compositions, the future of gold alloys is bright, promising exciting developments and applications.